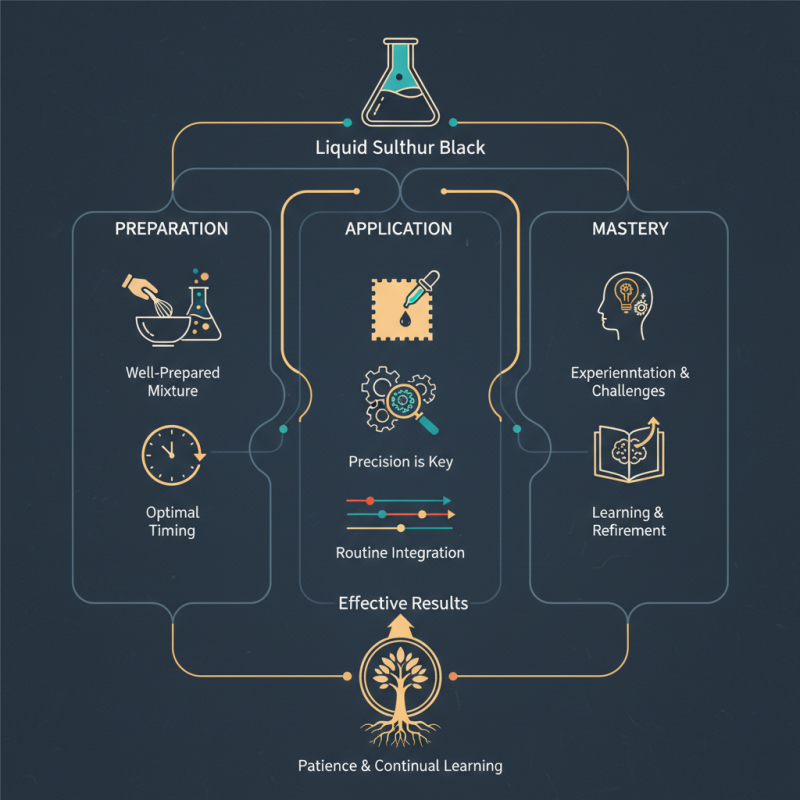

How to Use Liquid Sulphur Black for Effective Results?

liquid sulphur black is a powerful tool in various applications. Using it effectively can yield remarkable results. This guide will delve into crucial methods for integrating liquid sulphur black into your routine.

Many people overlook the importance of proper usage. Applying it just any way can lead to unsatisfactory outcomes. Precision is key. Ensure the mixture is well-prepared. This will maximize effectiveness. Timing also plays a role. It is essential to understand when to apply it for optimal results.

Experimentation may lead to unexpected challenges. You might find that what works for one purpose may not suit another. Each experience adds to your understanding. Reflection on these instances is vital. In doing so, you can refine your approach. Ultimately, mastering liquid sulphur black requires patience and continual learning.

Understanding Liquid Sulphur Black: Composition and Applications

Liquid Sulphur Black is widely used in various industries. Its unique composition includes elemental sulfur and carbon compounds. This mixture gives it distinctive properties, making it suitable for numerous applications, such as dyeing textiles and treating soils.

In textile dyeing, Liquid Sulphur Black provides deep, rich colors. According to recent industry reports, it can achieve up to 90% color fastness when properly applied. The dyeing process must be optimized, as inconsistent application can result in uneven coloration. This is a common issue many manufacturers face, often leading to customer complaints.

In agriculture, Liquid Sulphur Black is used to improve soil health. Sulfur is essential for plant growth. It helps in chlorophyll production and enhances nutrient absorption. Studies show that sulfur deficiencies can reduce crop yields by as much as 30%. However, excessive application can lead to soil acidification, highlighting the need for balanced use. Understanding these factors is crucial for obtaining effective results in both dyeing and agricultural applications.

Preparing for Application: Safety Measures and Equipment Needed

When preparing to apply liquid sulphur black, safety measures are paramount. This chemical can pose risks, so understanding protective equipment is essential. Research shows that long-term exposure can lead to respiratory issues and skin irritation. Always wear gloves and masks. Protective goggles are necessary to shield your eyes from splashes.

Consider the area of application. Work outdoors whenever possible. Ensure good ventilation in enclosed spaces. A fan or open windows helps disperse fumes. Proper clothing is crucial too. Wear long sleeves, pants, and closed shoes to prevent skin contact.

Tips: Regularly inspect your equipment. Check for leaks or damage before use. Never use sulphur black without safety gear. If you feel lightheaded, take a fresh air break immediately.

Always read the safety data sheet for specific details. Taking these steps ensures a safer experience.

Step-by-Step Guide to Applying Liquid Sulphur Black Effectively

Applying Liquid Sulphur Black can lead to impressive results, but it requires a precise approach. Start by preparing the application area. Ensure it's clean and free from debris. Wear gloves and eye protection. This step is often overlooked, but safety should be a priority.

Next, dilute the liquid sulphur according to the instructions. Too much concentration can damage plants or surfaces. Use a spray bottle or a brush for application. Spread evenly to avoid streaks. Sometimes, people rush this step. Take time to cover all areas properly.

After applying, monitor the treated surface regularly. Look for any changes or reactions. This part often reveals mistakes, such as uneven application or over-saturation. It’s essential to reflect on the process to improve future applications. Adjust your technique based on these observations to achieve better results next time.

Tips for Achieving Optimal Results with Liquid Sulphur Black

Liquid Sulphur Black can be a powerful tool if used correctly. To achieve the best outcomes, start by preparing your surfaces carefully. Clean the area you intend to treat. Any dust or debris can interfere with the results. This step seems simple, yet it is crucial. You might forget it, thinking it won’t matter, but it does.

When applying Liquid Sulphur Black, consistency is key. Use a steady hand. Avoid applying too thick a layer. A thin, even coat ensures better absorption and desired color. If you rush the application, you may end up with blotches. Patience helps create a uniform finish.

After applying, allow it to dry fully. This can take time, which many people don't anticipate. Be prepared to wait. Rushing this step can lead to uneven results. You might think checking if it’s dry is enough, but touch and feel will help. Pay attention to detail; it makes a significant difference. Remember, practice makes perfect. Don't be discouraged by early mistakes; use them as learning experiences.

Post-Application Care: Maintenance and Troubleshooting Techniques

After applying liquid sulphur black, proper care is crucial for optimal results. Ensure the treated area remains undisturbed for at least 24 hours. This allows the product to bond effectively. Avoid heavy rains and irrigation immediately after application. If unexpected weather occurs, check the area for any runoff or pooling.

**Tip:** Monitor the area closely for the first week. Look for any uneven coloring or areas that appear lighter. If you notice inconsistencies, a second application may be necessary to achieve uniformity. Timing is key—don’t rush this process.

Post-application, maintain the area by checking for signs of wear or fading. In bright sunlight, the effects may diminish faster. Regular assessment can help you catch issues early. The strength of the color can vary; don’t be discouraged by imperfections.

**Tip:** A light wash can sometimes restore appearance. Use gentle soap and water. Avoid harsh chemicals, as they can strip the sulpher coating. Over time, and with proper care, the treated surface should provide pleasing results.